About Studer S33 Grinder

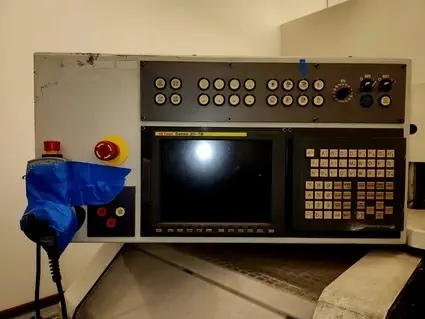

The Studer S33 CNC Grinder is a highly regarded precision grinding machine known for its versatility, reliability, and exceptional performance in industrial applications. It is widely used for internal and external cylindrical grinding, making it ideal for a variety of industries including automotive, aerospace, and medical device manufacturing. Here’s an overview of the Studer S33 CNC Grinder: Studer S33 CNC Grinder Overview: The Studer S33 is a high-precision, CNC-controlled cylindrical grinding machine that excels in medium to large-scale production environments. With a focus on flexibility, precision, and automation, the S33 offers a robust solution for high-tolerance grinding tasks, particularly for parts with complex geometries. The machine is engineered for a wide range of applications and supports multiple grinding processes, including: Internal Grinding External Grinding Face Grinding Spline Grinding Key Features: High Precision and Flexibility: The Studer S33 is designed to grind both internal and external surfaces of workpieces with high precision, achieving tolerances in the micrometer range. Excellent for grinding of complex shapes, particularly those requiring very tight tolerances. Robust Construction: Built with a rigid, solid frame that minimizes vibrations, ensuring the highest grinding accuracy. Offers excellent stability, even when working on larger workpieces, contributing to precision and consistency. Advanced CNC Control: The S33 comes with FANUC 31i-B CNC control system, providing a user-friendly interface, easy integration, and flexibility in automation. Supports multiple grinding operations, from simple to highly complex parts, with ease of programming and precise control over grinding parameters. Grinding Wheel Speeds: The S33 is equipped with a high-speed grinding wheel spindle, capable of speeds up to 45,000 rpm (depending on configuration), enabling high-efficiency grinding with minimal wear on the wheels. Versatility: Capable of grinding a wide variety of materials, including steel, carbide, and ceramics. Supports various grinding methods, such as profile grinding, form grinding, and high-precision grinding. Automated Features: Optional automated features like a robotic loader, automatic workpiece handling, and in-process gauging systems to reduce manual intervention and increase throughput. Technical Specifications: Max Workpiece Length: 300 mm (varies with configuration) Max Workpiece Diameter: 300 mm Grinding Wheel Speed: Up to 45,000 rpm (depending on configuration) Spindle Speed: 1,000 rpm to 6,000 rpm (variable) Table Travel: Up to 350 mm Control System: FANUC 31i-B (with intuitive touch-screen operation) Power Supply: Typically 380V, 50Hz Dimensions: Approx. 3,000 mm x 2,000 mm x 2,000 mm (depending on machine configuration) Applications: Automotive Industry: Grinding components such as crankshafts, camshafts, and transmission parts that require high precision and finish. Aerospace: Used for grinding turbine blades, landing gear components, and other critical aerospace parts. Medical Devices: For grinding medical implants and instruments requiring high surface quality and tight tolerances. Tool & Die: Precision grinding for molds, dies, and precision parts used in manufacturing. Advantages: Precision Grinding: The S33 delivers exceptional precision, making it suitable for industries requiring micron-level tolerances. User-Friendly Interface: The FANUC CNC control is easy to program and operate, ensuring efficient machine setups and grinding operations. Customization: The machine can be customized to meet specific production needs, including automation, wheel configurations, and specific software packages. High Productivity: With high grinding speeds and the option for automation, the Studer S33 is designed for optimal throughput while maintaining accuracy. Key Benefits: Increased Production Efficiency: The CNC system allows for precise, repeatable operations that are essential for mass production or high-precision manufacturing. Minimal Setup Time: Quick changeover times and ease of setup contribute to reduced downtime between production runs. Enhanced Surface Quality: The high-precision capabilities ensure excellent surface finishes, which is critical for parts used in high-performance or safety-critical applications. Options and Add-Ons: Automatic Wheel Changing System: For fully automated grinding processes, reducing manual labor and increasing efficiency. In-Process Measurement: Integrated measuring systems to monitor grinding progress and ensure parts meet exact specifications during operation. Robotic Loading/Unloading: For fully automated and high-speed production lines. Conclusion: The Studer S33 CNC Grinder is an exceptional choice for industries requiring high-precision cylindrical grinding, especially for complex, high-tolerance components. With advanced CNC controls, a solid build, and customizable options, it offers both versatility and reliability in high-precision manufacturing environments.